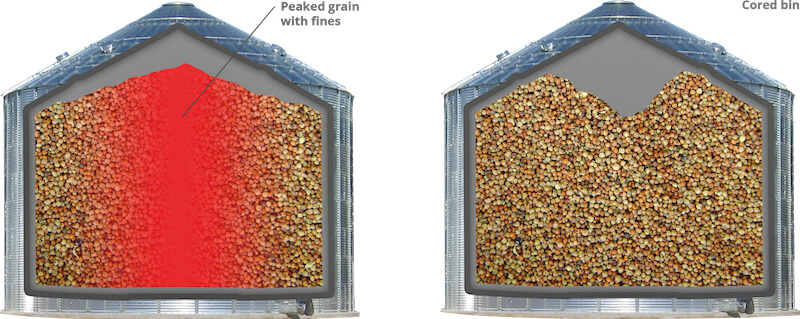

When the grain is finally stored, a significant part of the work is done. The harvest is protected from the elements, but that doesn’t mean you’re safe from all risks! Heated, moldy, crusty grains, etc. Be vigilant, there are still plenty of unforeseen events waiting to happen! Whether you’re storing 100 tons or 10,000 tons of grain, the risks remain the same. Even if your dryer has cooled the grain, there's still a risk of overheating, particularly in the heart of the bin. Filling from the center causes compaction that prevents proper ventilation. Broken grain accumulates in the center, while intact grain rolls down the sides. When harvested at 20°C, grains reach 25-28°C when they leave the dryer. At these temperatures, they can continue to “sweat”, risking thermal runaway, which can occur very quickly. The solution? Remove the core from your bin. The larger the bin, the greater the risk, and the greater the financial consequences. In addition to being highly dangerous, the grain cone formed during filling prevents the grain mass from cooling down evenly. As your bin cools, air will only pass close to the wall. By removing the central part of the bin, you unpack the core and level out your grain, allowing even ventilation throughout the entire mass. Tired of climbing to the top of your bin to see if your grain is cold? Use our wireless probes to measure the temperature of the air leaving your grain bin. No more ladders! Just track the temperature from your cell phone. Want to know more? Read our blog!